Why Centrifugal Spray Dryers Are the Gold Standard in Modern Drying Technology

In today's fast-paced manufacturing environment, the need for efficient and reliable drying systems is more pressing than ever. Among the various technologies available, the centrifugal spray dryer stands out as a gold standard for converting liquids into high-quality powders. This spray dryer equipment offers unmatched speed, uniformity, and adaptability.

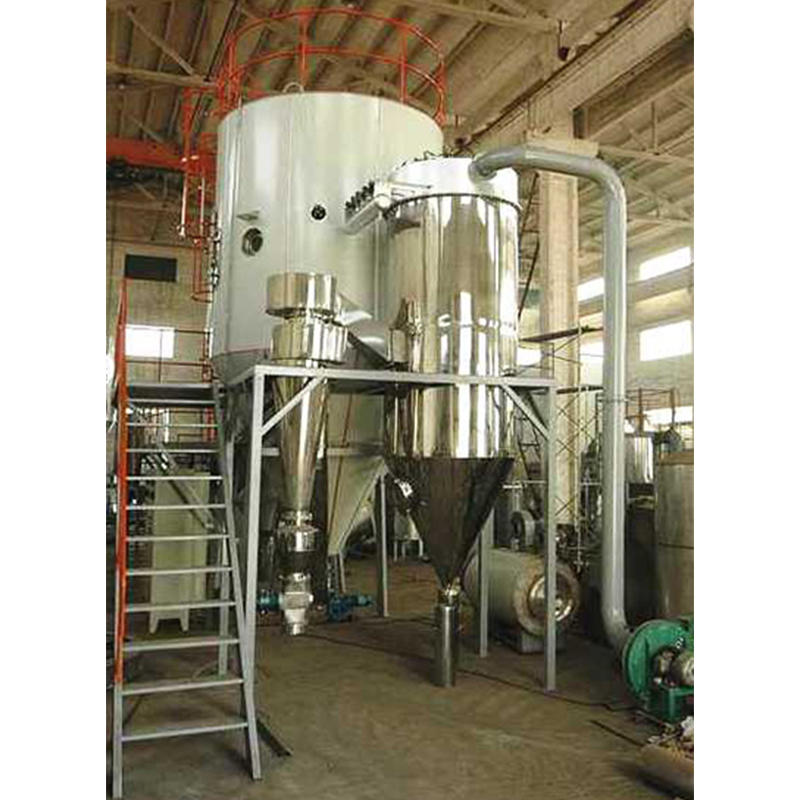

How Centrifugal Spray Drying Works

The centrifugal spray drying machine employs a rotary atomizer that spins at high speed to convert liquid feed into fine mist droplets. These droplets are then exposed to a stream of hot air inside a large chamber. The rapid heat transfer causes immediate evaporation, resulting in fine dry powder that settles at the bottom or is collected using a cyclone separator.

Unlike conventional drying methods, centrifugal atomizing dryers ensure extremely fast drying with minimal thermal impact. This makes them ideal for sensitive substances like proteins, herbal extracts, and live microorganisms.

Key Benefits of Spray Dryer Equipment

Speed and Efficiency: The drying process is completed in seconds, significantly reducing production time.

Product Uniformity: Fine control over droplet size and drying parameters results in consistent particle size and quality.

Versatility: Capable of handling both heat-sensitive and heat-stable materials.

Scalable Design: From laboratory-scale units to full industrial plants, spray dryers are adaptable to various production scales.

These benefits make centrifugal spray dryers an essential part of industries ranging from food processing and pharmaceuticals to advanced materials and biotechnology.

Common Uses and Industrial Applications

Centrifugal spray drying is applied in numerous sectors:

Food Industry: Instant coffee, milk powders, protein supplements, flavoring agents.

Pharmaceutical Sector: Drying antibiotics, vaccines, and other biologics.

Chemical Industry: Drying of pigments, polymers, and catalysts.

Agricultural Products: Production of pesticides, fertilizers, and seed coatings.

Each of these industries relies on the spray drying system to produce powders that are not only dry but also free-flowing and uniform.

Technological Enhancements

Modern spray drying machines come equipped with advanced controls and monitoring systems. Real-time adjustments to inlet air temperature, feed rate, and atomization speed allow manufacturers to fine-tune the drying process for optimal results.

Innovations such as closed-loop systems, HEPA filtration, and solvent recovery options also ensure environmental compliance and operational safety.

English

English русский

русский عربى

عربى Türk

Türk