Who Are We?

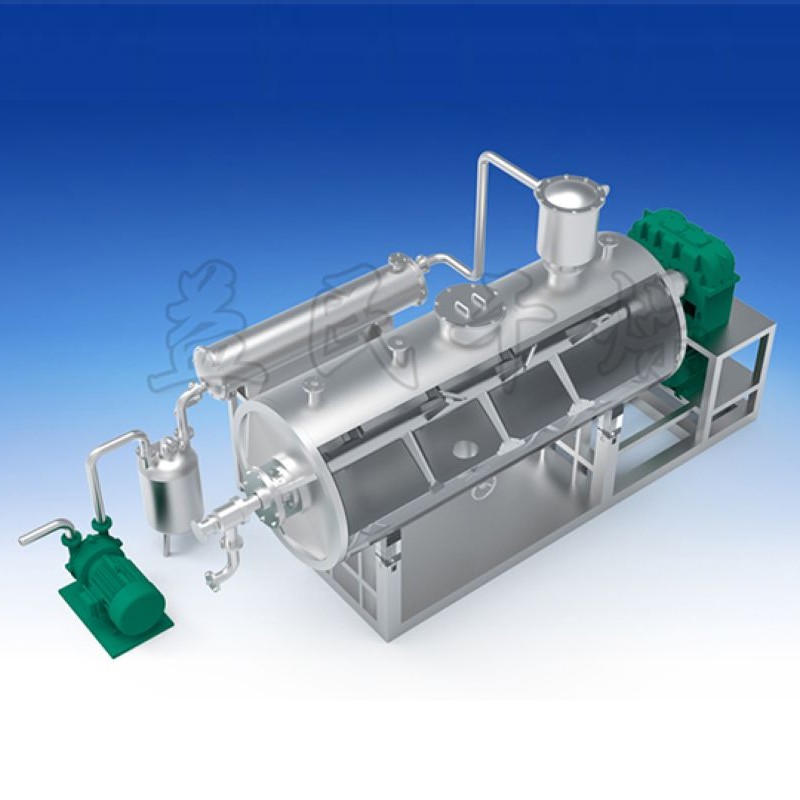

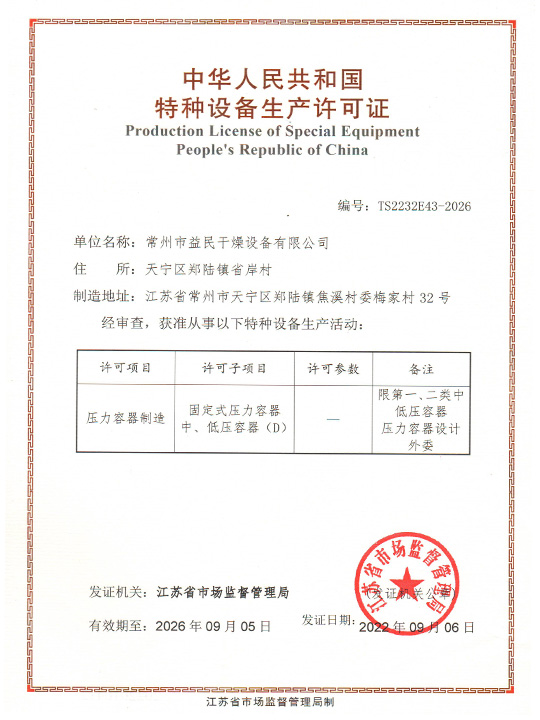

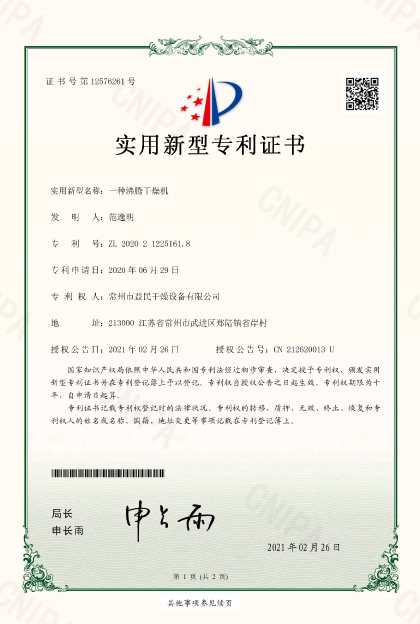

Changzhou Yimin Drying Equipment Co., Ltd. is China SYH 3D Movement Mixer suppliers and OEM/ODM SYH 3D Movement Mixer company, located in the birthplace of China's drying equipment industry - Jiaoxi Industrial Park, Zhenglu Town, Changzhou City. It is adjacent to the Beijing-Shanghai Expressway, Shanghai-Nanjing Railway, and 5 kilometers from the Hengshan Crossing of the Shanghai-Nanjing Expressway. It is a key backbone enterprise in China's drying industry and pharmaceutical machinery. The company currently covers an area of 33,000 square meters and a building area of 18,000 square meters. The company has modern large-scale production workshops and equipment, fixed assets of more than 80 million yuan, and more than 120 employees. The founder of the company, Mr. Fan Yiming, has been committed to the research, production and operation of drying equipment for more than 20 years. At the same time, he has also brought together a group of high-quality talents integrating scientific research, design, production and service, and has long-term horizontal cooperation with relevant colleges and universities to continuously update and develop products.

At present, the company has more than 180 sets of processing equipment and strong technical force. It produces more than 2,000 sets of various drying, mixing, granulating, crushing, dust removal, powder screening and other equipment annually. The products have developed into eight series with more than 300 specifications and varieties, which are widely used in pharmaceutical, chemical, food, feed, mining, agricultural and sideline products, electronics, light industry and other industries. The products are distributed throughout the country and exported to the United States, Japan, Russia, Hong Kong, Taiwan and other places.

The factory also has a large test workshop with a full range of prototypes. Customers are welcome to bring materials for testing and ordering.

Beyond Pharmaceuticals: The Broad Industrial Applications of Dry Granulation

Beyond Pharmaceuticals: The Broad Industrial Applications of Dry Granulation What is the main difference between batch and continuous powder mixers?

What is the main difference between batch and continuous powder mixers?

English

English русский

русский عربى

عربى Türk

Türk