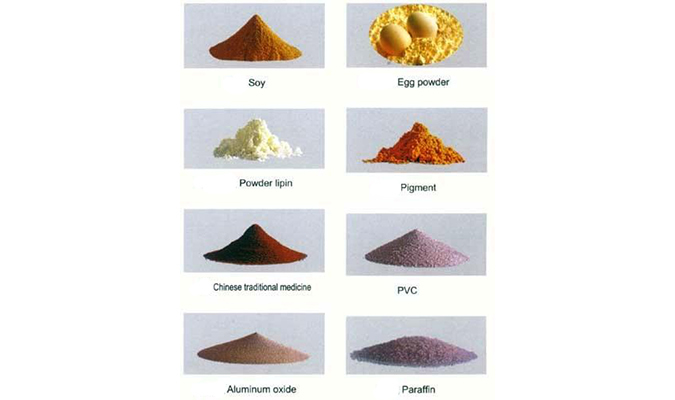

The centrifugal spray dryer is widely used in liquid technology shaping applications and other industrial drying applications. The drying equipment is most suitable for producing powdered or granular solid products from liquid state materials, such as solutions, emulsions, suspensions and pastes. When size distribution, residual water content, stacking density and shape of the final product have certain standards, spray drying is the desired drying method.

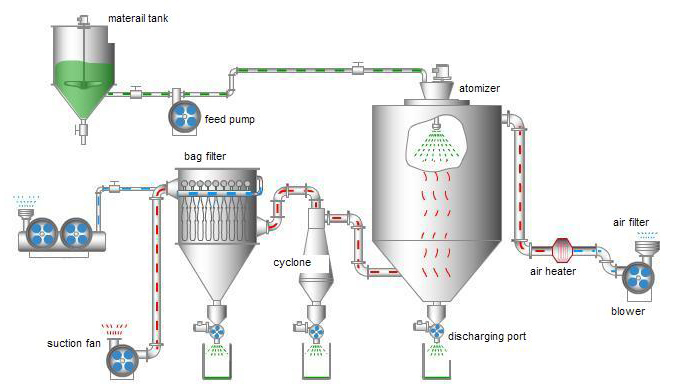

The centrifugal spray dryer heats filtered air that is then pumped into the hot air distributor on the top of the dryer. The air then enters the drying room evenly as liquid materials are sent through the centrifugal atomizer on the top of the machine and are atomized into tiny droplets which are quickly heated and dried. The finished products are discharged from the bottom of the drying tower and from the cyclone separator. Waste air is exhausted by a suction fan.

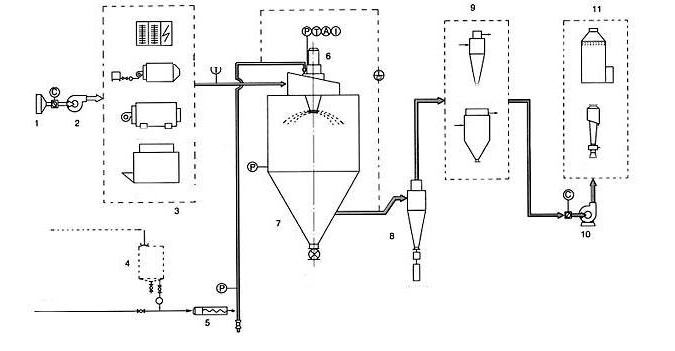

1. Air filter

2. Blower

3. Air heater

4.Feed bin

5.Feed pump

6.Atomizer

7.Drying chamber

8.First powder catcher (cyclone)

9.Second powder catcher (cyclone or bag filter)

10.Suction fan

11.Exhaust air filter (water film scrubber)

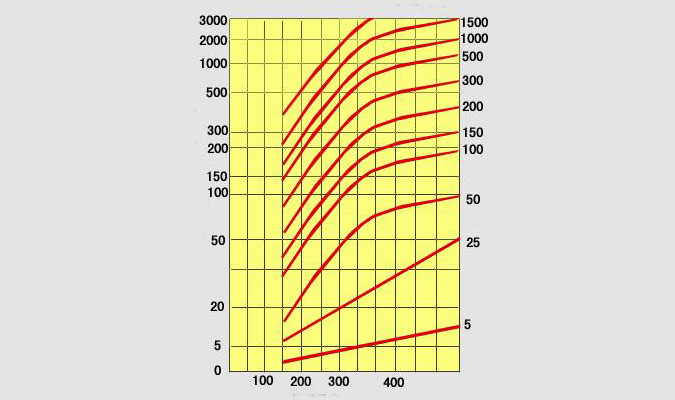

| Specification | LPG5 | LPG25 | LPG50 | LPG100 | LPG150 | LPG200-3000 | |

| Inlet temperature | ≤ 350°C | ||||||

| Outlet temperature | 80-90°C | ||||||

| Evaporating rate (kg/h) | 5 | 25 | 50 | 100 | 150 | 200-3000 | |

| Rotating speed(rpm) | 25000 | 22000 | 21500 | 18000 | 18000 | 15000 | |

| Dia. of atomizing tray(mm) | 50 | 120 | 120 | 120 | 150 | 180-340 | |

| Heat source | Electricity | Electricity | Electricity+ steam, oil fuel, gas, or coal | ||||

| Electrical-heating power | 9 | 45 | 60 | 81 | 99 | ------------- | |

| Dry powder Yield | ≥ 95 | ||||||

| Installation Size For reference | A(mm) | 1000 | 1290 | 1730 | 2500 | 2800 | Decided according to actual condition |

| B(mm) | 2100 | 3410 | 4245 | 5300 | 6000 | ||

| C(mm) | 2300 | 4260 | 4645 | 6000 | 6700 | ||

| φ D(mm) | 1060 | 1800 | 2133 | 2560 | 2860 | ||

| E1(mm) | 1050 | 1200 | 1640 | 2100 | 2180 | ||

| E2(mm) | 1050 | 1200 | 1640 | 2100 | 2180 | ||

| F(mm) | 750 | 1000 | 1250 | 1750 | 1970 | ||

| G(mm) | 530 | 1700 | 1750 | 1930 | 2080 | ||