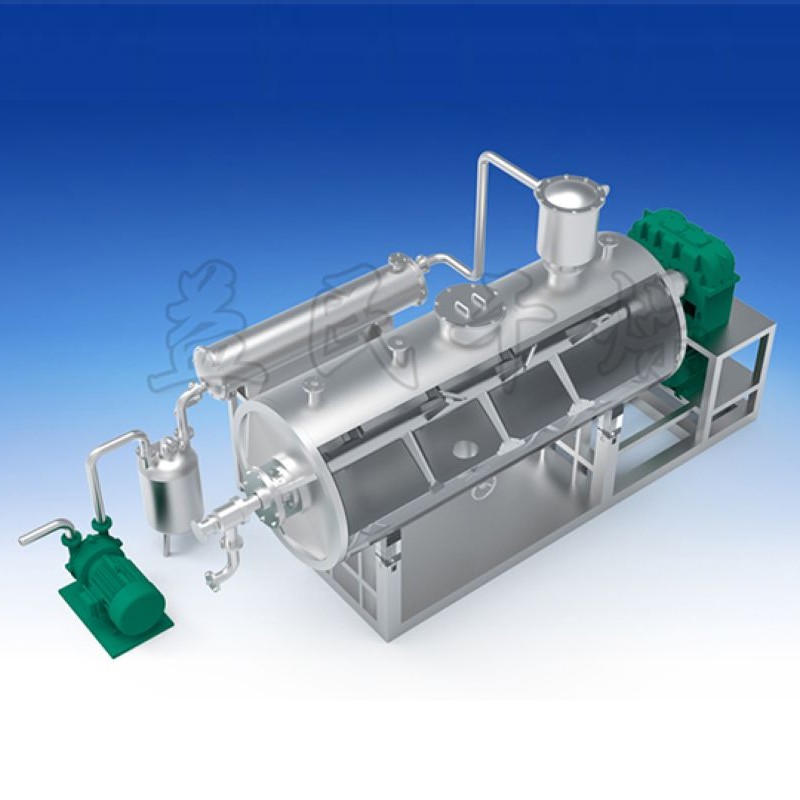

The Centrifugal Spray Dryer stands as a cornerstone technology in material processing, essential for transforming liquid feeds into high-quality, free-flowing, and uniform dry powders. Widely adopted ...

-

Beyond Pharmaceuticals: The Broad Industrial Applications of Dry Granulation

Beyond Pharmaceuticals: The Broad Industrial Applications of Dry GranulationWhile often spotlighted for its critical role in pharmaceutical manufacturing, dry granulation is a versatile and indispensable process with significant applications across a multitude of other major ...

-

What is the main difference between batch and continuous powder mixers?

What is the main difference between batch and continuous powder mixers?The fundamental distinction between batch and continuous powder mixers lies in their operational mode and, consequently, their suitability for different production needs. It boils down to how the ingr...

English

English русский

русский عربى

عربى Türk

Türk